Welcome everyone to Project Ulfberht. ( It's a sword if you don't know. Wiki page and a good video on it. )

I’ve been a big fan of Jang’s rustler for years so that’s been a huge influence on this build but I can’t go too light weight as there is a weight rule locally ( 1725 grams ) so I’m not going to cut as much to start with. I can always remove more later on anyway.

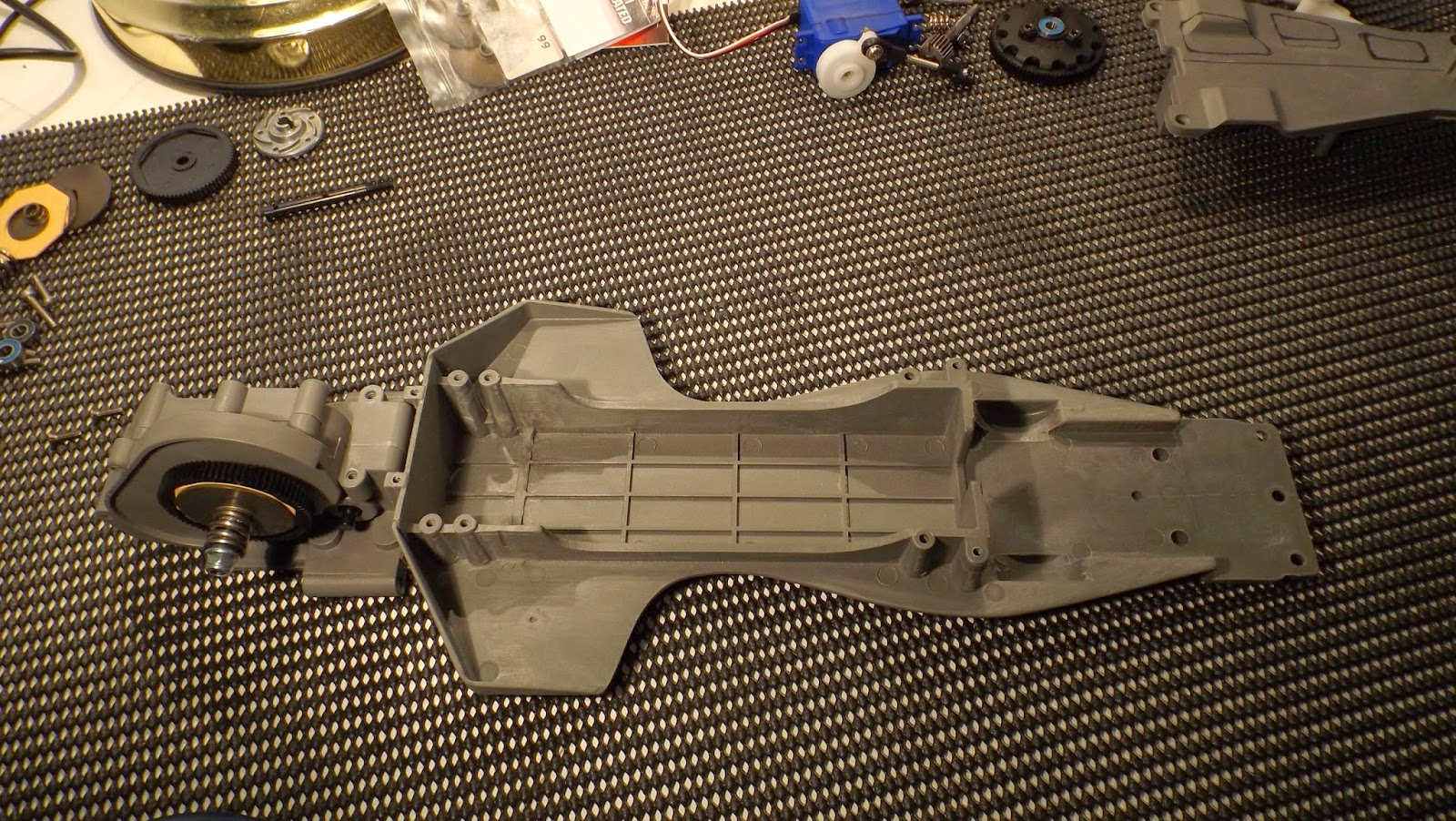

A few hours with a dremel and a hot knife and we get this. Just needs a final sand and I can Rit dye it.Now if you’ve noticed that slipper isn’t stock, well fully stock anyway. Though nor is it an Associated slipper. I want get an ST racing top shaft later on but this will do for now. Anyway, I wanted something better than the normal one and I wanted to use a better spur gear. So a few minutes with the drill and a vice to get this.

Half Traxxas and half AE. Now this was actually somewhat tricky to make with the lack of a lathe. I used a hand drill, 5mm and 4mm drill bits. You need to drill out the spur to 5mm to fit on the top shaft and also very carefully drill out the AE slipper plate. Drilling the slipper plate with it been held in a vice is tricky as you don’t want to scratch of bend the hole/tube but it’s the only way to hold it in a vice as it’s too thin to hold it any other way. So with the drill bit drilling into the hole on the other side, you’re drilling on two flat plates. The flat plates/flat spots are to hold onto the flat on the normal AE shaft. I guess you could also dremel the Traxxas one but more effort. I’ll most likely do it later on though.

The drill bit will bite very hard and it takes a lot of time to get to to cut right. Tapping fluid or just normal shock oil helps though. Now once you have those drilled out, you need to drill the little spring holder out to 4mm to clear the threads on the shaft. After that, just put it all together and you have a much nicer slipper clutch.

The drill bit will bite very hard and it takes a lot of time to get to to cut right. Tapping fluid or just normal shock oil helps though. Now once you have those drilled out, you need to drill the little spring holder out to 4mm to clear the threads on the shaft. After that, just put it all together and you have a much nicer slipper clutch.

That's progress so far, an update will follow shortly.

-Jeremy

No comments:

Post a Comment